Spiral Wound Gasket Installation Procedure To Install

Installation Procedures which are available in eight languages. These are intended to complement the more detailed manufacturers’ documents produced by the member.

Flange Conditions

Sealed joints can be affected by a variety of reasons:

Non-Parallellism

The two pipes are parallel with each other, but the surfaces of the flangesare not. The result is an uneven load distribution on the gasket whereone side will be understressed and not effective seal present, and the otherside will be oversstressed where crushing can occur, losing the seal.

Axial or Radial Misalignment

The two flanges are parallel with each other but are not in line of eachother (non-concentric). The result is an uneven load distribution on thegasket where one side will be understressed and not effective seal present, andthe other side will be oversstressed where crushing can occur, losing the seal.

Excessive Gap between Flanges

The two flanges are not parallel with each other. The result is an unevenload distribution on the gasket where one side will be understressed and noteffective seal present, and the other side will be oversstressed where crushingcan occur, losing the seal.

Excessive Flange Gap

The flange faces are too far apart from each other which uses a majority ofthe bolt load to pull them together. This results in lower seating stressbeing applied to the gasket. If the effective seating stress is too low,the seal will be lost.

Flange Rotation

The flanges are rotated outward, crushing the outeredge of the gasket and unloading the inner edge. This is a result of ahigh internal pressure and high bolt load needed to seal the pressure. The effective seal area becomes very small and susceptible to blowoutSurface Conditions on Flange Face

Three conditions exist for the surface of the flange faces

Warpage

Warped flanges will create high and low areas of bolt load, making the sealsusceptible to a blowout.

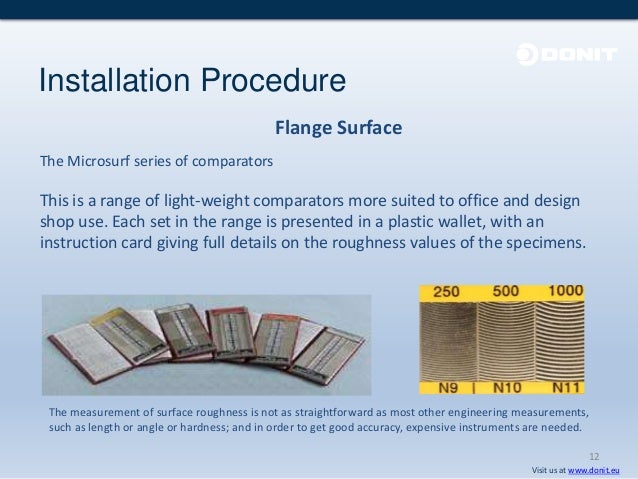

Surface Finish

The surface should be machined finish, between 125 - 250µm.

Willem pro4 isp software solutions free. Thanks, Doug. Or even running XP or Windows 98 in a VMware Player virtual machine with the parallel port forwarded to it would be a way to test it too •.

Imperfections

Pitting caused by corrosion, tool marks from chisels etc., or chemical orsteam damage on the flange can all create leak paths.

Fasteners and Lubrication

Fasteners are the only method of applying and maintaining a compressive loadon a gasket. Force is applied through a wrench and torque that isdeveloped through hand or impact wrench. This creates tension in the boltbody due to the interaction of the threads. Tension pulls the flangestogether, placing force on the gasket surface area. This is calledsealing stress.

There are four key factors to effective bolting of flanges

Fastener Quality

Bolts/studs must be chosen to suit the load required for an effectiveseal. For example, grade B7 bolts have a far higher tensile strength thangrade 8 bolts, and are required for certain flanges. Nuts and washersshould also be hardend to prevent galling and 'mushrooming'.

External Factors Affecting Performance

Service life of fasteners are to be considered as bolts will relax overtime, losing their ability to 'stretch' and hold their 'torque'. Temperature also has a big effect on bolts and should be considered whenchoosing fasteners for the application.

Lubricationof Fastener Components

Bolt threads, nut faces that contact the hardened washer, and both faces ofthe hardened washer need to be lubricated to ensure effective 'torque totension' transfer. If no lubrication is used during bolting, more offorce is required to compensate for the high coefficient of fricition whichmeans that less of the force applied is transferred to the gasket. Conversely, more of the force applied to the bolts is transferred to the gasketit every component is properly lubricated.

FastenerTorque and How to Apply itFastener Torque Schema

Fastener Torque Schema

The Fluid Sealing Association (FSA) guidelines should befollowed when torquing fasteners. Torque accuracy is critical to aneffective seal. Tools such as calibrated torques wrenches, hydraulictensioners and stretch control bolts provide a means of achieving torqueaccuracy.

Proper tightening sequences are highly recommended to prevent localizedoverloading of gasket sections.

Common Installation Misconceptions

NST Coating vs. Lubricants on Gasket Face

Misconception #1

'Cut gasket always stick, so put lube or anti-seize on thesurfaces'

Spiral Wound Gasket Installation Procedure To Installation

Historically compressed asbestos fibre gaskets were coated to help in theremoval process, which was common practice. Asbestos sheet material has alow percent of rubber binder which meant that the gasket would soften but notdisintegrate. Today however, non-asbestos compressed sythetic fibre sheetmaterial has more that 60% rubber in it, so grease and anti-seize compoundswill attack the gasket. The gasket typically loses its thickness andconsequentially its sealing stress. Friction between the flange face andthe gasket drops and the gasket then extrudes out of position.

A solution to the sticking gasket has been found in the form of a non-stickcoating(NST). Non stick coating is a mica based coating that is inertwith high temperature ratings and can be found on Klingersil CSF materials.

Misconception #2

Spiral Wound Gasket Installation

'If an installed cut gasket leaks a bit, just torque it down more'

Historically compressed asbestos fibre gaskets were re-torqued if theystarted to leak which would temporarily solve the problem. This waspossible because the asbestos sheet has a low percentage of rubber binder and ahigh percentage of asbestos fiber holding it together. Rubber bindersharden and become brittle after exposure to high temperatures. So,today's non-asbestos compressed fiber sheets with more than 60% rubber areprone to cracking and creating a blowout failure during a retorquing after hightemperature service.

Misconception #3

Measurements For A Spiral Wound Gaskets

'I switched from a cut gasket to a spiral wound, and now the jointalways leaks'

FL Studio (Fruity Loop) 20.0.5.681 Torrent Crack Download [2019] Torrentsoft November 4, 2018 0. Projects are well suited with the Mac and Windows variations. If the same 3rd party plugins hooked up, you can’t do something so you can proportion your initiatives or Zip file. In this article, we will be going to show you how to download Fruity Loops for mac free (now called FL Studio). FL Studio and is a popular beat making software that is only available for Windows Platform. Buy FL Studio and get the latest version plus all future FL Studio updates free.We believe you should have the functionality you paid for, bug-fixed, developed. Fruity loops studio 6. FL Studio 20.1.1.795 Crack Fruity Loops Torrent Free Key Download. January 11, 2019 by vickych 25 Comments. FL Studio 20 Crack Mac + Windows Full Version Reg Key Here. The created composition or cycle can be exported to a MIDI file or wave, an mp3 data file. Mac Update 20.0.3 [Build 38]. Besides that FL Studio has some really good plugins itself which I use a lot. Read more about what Power Users are saying about FL Studio. Fruity Edition. Basic melody & loops creation. Producer Edition. Full song creation & audio recording.

Spiral wound gaskets require a much higher minimum seating stresswhere the torque values used for cut gaskets are much lower. So, if thebolts are well used, they cannot transfer the torque to the gasket surface tocreate a proper seal.